November 18, 2025

to update

Map the future with 3D-printed titanium Apple Watch cases

It started with a fanciful idea: What if 3D printing — which has historically been used to create prototypes — could be leveraged to produce millions of packaging identical to Apple’s exact design standards, using high-quality recycled metals?

“It wasn’t just an idea, it was an idea that wanted to become a reality,” says Kate Bergeron, Apple’s vice president of product design. “Once we asked that question, we immediately started testing it. We had to prove, through continuous prototyping, process improvement, and a massive amount of data collection, that this technology was capable of meeting the high level of quality we required.”

This year, all titanium cases for Apple Watch Ultra 3 and Apple Watch Series 11 were 3D printed using 100 percent recycled titanium powder, a feat not previously considered possible on a large scale. Every team at Apple rallied behind a common ambition. The polished mirror in Series 11 must be pure. The Ultra 3 had to maintain its durability and lightweight form to meet the demands of everyday adventurers. Both also had to be better for the planet without compromising performance, and use the same or better quality materials.

“At Apple, every team holds green as a core value,” says Sarah Chandler, Apple’s vice president of Environment and Supply Chain Innovation. “We knew that 3D printing was a technology with great potential for material efficiency, which is critical to getting to Apple 2030.”

Apple 2030 is the company’s ambitious goal to be carbon neutral across its entire footprint by the end of this decade, which includes the manufacturing supply chain and lifetime use of its products. Indeed, all of the electricity used to manufacture the Apple Watch comes from renewable energy sources like wind and solar.

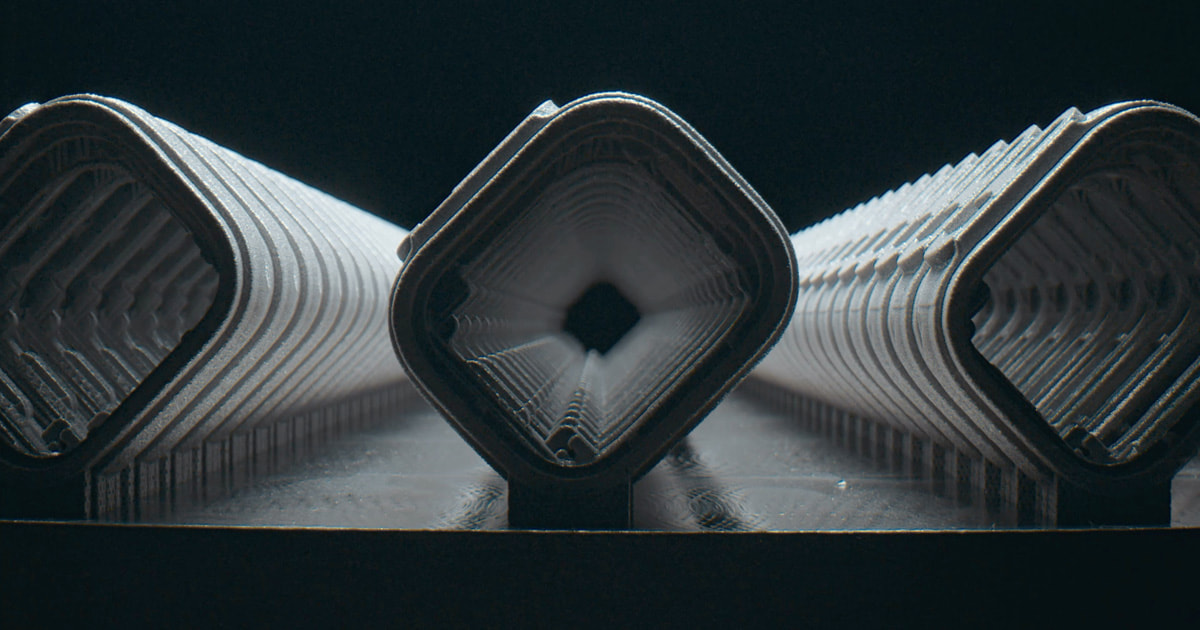

Using the additive process of 3D printing, layer after layer is printed until the object is as close to the desired final shape as possible. Historically, processing of forged parts was a subtractive process, requiring the removal of large portions of material. This transformation enables the Ultra 3 and Series 11 titanium cases to use only half the raw materials compared to previous generations.

“A 50 percent reduction is a huge accomplishment—you’re getting two hours out of the same amount of material used in one hour,” explains Chandler. “When you start mapping that out, the savings to the planet are enormous.”

In total, Apple estimates that more than 400 metric tons of raw titanium will be saved this year alone thanks to this new process.

Over the past decade, Apple has been experimenting with 3D printing while the industry itself was just beginning to take off. In hospital laboratories, doctors were using the first 3D-printed prosthetic limbs and organs, and even outside Earth’s atmosphere, astronauts were discovering the speed and ease of 3D-printing vital tools while aboard the International Space Station.

“We’ve watched this technology mature for a long time and have seen its prototypes become more representative of our designs,” says Dr. G. Manjunathaya, senior director of manufacturing design for Apple Watch and Vision at Apple. “Our goal has always been to use less materials to make our products. Previously, we couldn’t make cosmetic parts on a large scale using 3D printing. So we started experimenting with 3D printing on metals to make cosmetic parts.”

For Apple, functionality, beauty, and durability are top priorities. Add to that scalability, along with rigorous reliability and performance testing and even breakthroughs in materials science, all while ensuring Apple doesn’t lose any progress on its 2030 decarbonization goals.

Looking down from above, you’ll find rows of blocks protruding from the ground like white Lego skyscrapers, buzzing day and night. These are the 3D printers hard at work building the titanium cases for the Apple Watch Ultra 3 and Series 11.

Each machine contains a galvanometer containing six lasers, all working simultaneously to build up layer after layer – more than 900 times – to complete a single case. But even before the printers can start, the raw titanium must be crushed into powder, a process that involves carefully adjusting the oxygen content to reduce the properties of titanium that become explosive when exposed to heat.

“This was cutting-edge materials science,” Bergeron says.

“The powder should be 50 microns in diameter, which is like very fine sand,” explains Manjunathaya. “When you hit it with a laser, it behaves differently if it has oxygen or not. So we had to figure out how to keep the oxygen content low.”

“Determining this thickness so that each layer is exactly 60 microns means squeezing this powder very precisely,” adds Bergeron. “We had to move as quickly as possible to make this scalable, while moving as slowly as possible to be accurate. This allowed us to be efficient, while still achieving our design goals.”

Once the printers are finished, the operator vacuums the excess powder from the build plate in a process called raw powder removal. Because the designs are printed on the semi-finished form of all the interlocks required in the can, powder can still remain in the nooks and crannies of the cans. The ultrasonic shaker ensures that this residual powder is removed during the fine powder removal stage.

During the singling process, a thin, electrified wire is spread between each tray, while a cooling liquid is simultaneously sprayed to keep the heat generated by the cutting process low. An automated visual inspection system then measures each case, verifying its dimensional and cosmetic accuracy. This is the final quality check to ensure that the packages are ready for final processing.

“Mechanical engineers must be the most skilled puzzle solvers in the entire world,” Bergeron says. “They take the circuit board, the display, and the battery — all the things that go inside the case during final assembly — and make them fit. We test along the way to make sure the watch works; then we add the software and run it for a while to make sure all the functions meet our requirements.”

Another major design improvement opened up is 3D printing: printing tissue in locations that were historically inaccessible in the forging process. For the Apple Watch, this meant being able to improve the waterproofing of the antenna housing on cellular models. Inside the case, the cellular models have a plastic-filled split to enable antenna function, and 3D printing a specific texture on the inner surface of the metal has enabled Apple to achieve a better bond between the plastic and the metal.

Putting the pieces of the puzzle together was a multi-year journey that began with a series of demonstrations and proofs of concept to improve the recipe, from the specific alloy composition, to the printing process itself. Having tested it on a much smaller scale in previous product generations, the team was confident in its ability to solve the unique challenges of working with titanium.

“We’re always trying to take those extra steps to allow us to take the next step,” Bergeron says. “This has now opened up the opportunity for more design flexibility than we had before. Now that we have achieved this feat at scale, in a truly sustainable way, and at the cosmetic and structural level we need, the possibilities are endless.”

This design flexibility has opened up another feature beyond the Apple Watch: the USB-C port on the new iPhone Air. By creating an entirely new port with a titanium casing that was 3D-printed using the same recycled titanium powder, Apple was able to make its incredibly thin and durable design a reality.

This is the magic that can happen when the laws of physics, material innovation, unparalleled design, and an unwavering commitment to the environment align.

“We are extraordinarily committed to systems change,” Chandler says. “We never do something just to do it once – we do it so that it becomes the way the entire system works. Our north star has always been to design products that are better for people and the planet. When we come together to innovate without compromising on design, manufacturing and our environmental goals, the benefits are exponentially greater than we could ever imagine.”

Click on Contacts

Sean Redding

apple

s_redding@apple.com

Nikki Rothberg

apple

nrothberg@apple.com

Apple Media Helpline

media.help@apple.com